Introduction

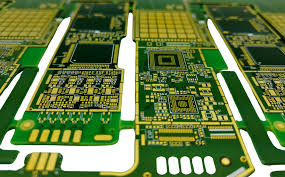

It is essential to consider several factors that allow the estimation of PCB manufacturing’s impact on product reliability to produce reliable PCBs. Material quality, manufacturing processes, trace width and spacing, thermal management, and proper quality control are the aspects discussed in this paper.

Material Quality

Material quality is the most critical aspect of PCB reliability. The longevity and field performance of high-quality PCBs rely heavily on the type of substrate, copper foil, and solder mask chosen. For example, an FR-4 high-grade substrate helps PCBs to resist moisture and thermal decomposition better than a lower-grade substrate. A study by the IPC Utilization of High Performance Materials 2005 found that high-quality PCBs can withstand severe environmental conditions and reduce the failure rate by 30% compared to lower-grade substrate PCBs.

Manufacturing Processes

More errors can lead to more defects; therefore, manufacturing processes are important. New manufacturing capabilities such as automated optical inspection and X-ray inspection test various factors in the process. For example, a firm utilizing AOI could have defect rates of 0.1 %, whereas manual inspections result in rates of over 0.5%. The use of these techniques ensures that each PCB meets high quality standards, leading to more reliable overall products.. The use of these techniques ensures that each PCB meets high quality standards, leading to more reliable overall products.

Trace Width and Spacing

Adequate trace width and spacing are vital to prevent an electrical failure. In high-density PCBs, maintaining sufficient spacing between traces is essential to preventing electrical shorts. Meanwhile, high-power applications benefit from increased trace width, which allows PCBs to handle more current.. When the trace width is 0.5 mm, the 1 amp current becomes too high for the trace to pass without overheating. Extracting by the same current from a trace with a smaller width of about 0.5mm may lead to overheating.

Thermal Management

Thermal management when properly handled doubles the life of a PCB. Technologically, PCB components degrade with time, and heat plays a crucial role in this process. Adequate thermal vias and heat sinks help manage the temperature of these electronic components. Data available shows that the life of electronic components doubles with a 10 oC reduction in temperature.

Quality Control

Good quality PCBs require strict quality control. The requirement means that all factors in production, including material procurement and final assembly, are consistent. A report by the IPC Utilization of high-performance materials 2005 shows that a PCB exhibits about a 40% failure rate during its life on the field. The report adds that adherence to high quality reduces about 40%. Visit our Thorough Guide for detailed pcb manufacturing information to learn more.